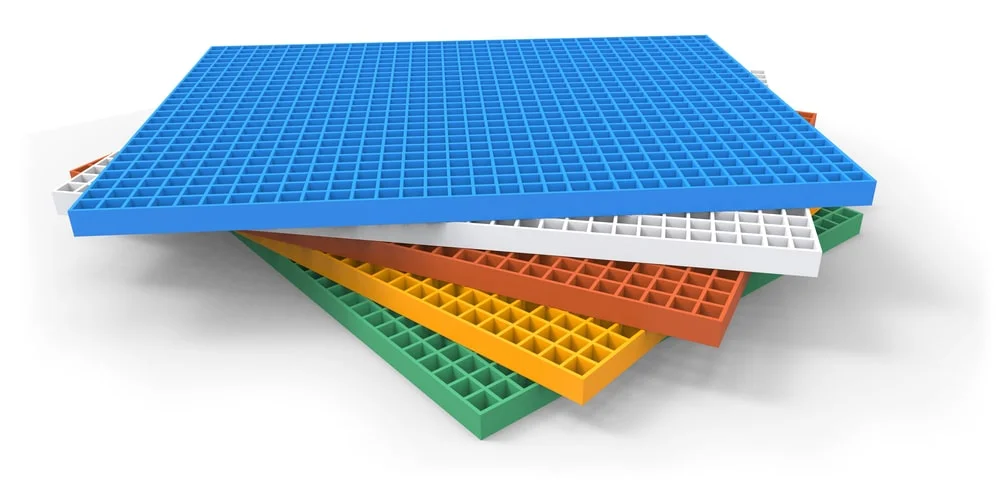

FRP Gratings

High-strength, lightweight composite grating solutions engineered for extreme corrosion resistance and electrical safety in industrial walkways and platforms.

frp

frpSystem Advantages

1. Key Performance Characteristics

Superior Corrosion Resistance:Immune to salt, moisture, acids, and harsh industrial effluents.

Strength-to-Weight Ratio:Significant load-bearing capacity while remaining much lighter than steel counterparts.

Slip Resistance:Available with grit-top surfaces or molded patterns for maximum traction in oily or wet areas.

Electrical & Magnetic Safety:Non-conductive and non-magnetic properties, ideal for high-voltage and sensitive electronic zones.

Low Maintenance:Zero requirement for painting, sandblasting, or galvanized coating over its entire lifespan.

2. Specialized Types of FRP Gratings

Molded Gratings:Bidirectional strength with high impact resistance, perfect for pedestrian traffic and light-duty platforms.

Pultruded Gratings:High-glass content strands for superior unidirectional load-bearing capacity in heavy-duty applications.

Covered Gratings:Standard grid panels with a solid top cover to prevent small objects from falling through and provide a smooth surface.

3. Industrial Applications

Chemical & Wastewater:Walkways and platforms exposed to corrosive chemicals and constant moisture.

Marine & Offshore:Saltwater-resistant flooring for docks, marinas, and oil rigs.

Power Generation:Non-conductive flooring around cooling towers, transformers, and sub-stations.

Food & Beverage:Sanitary, slip-resistant surfaces that withstand aggressive cleaning agents and spills.

4. Advantages Over Metal Alternatives

Zero Rusting:Unlike steel or aluminum, FRP does not oxidize or degrade in humid environments.

Reduced Installation Costs:Lightweight panels can be easily cut and installed without heavy lifting equipment or welding.

Fire Retardancy:Manufactured with specialized fire-retardant resins to meet strict industrial safety codes.

UV Stability:Engineered to withstand direct sunlight exposure without becoming brittle or fading.

5. Engineering Selection Criteria

Resin Choice:Selection between Polyester, Vinyl Ester, or Phenolic resin based on specific chemical exposure.

Load Profile:Determining whether molded (uniform load) or pultruded (span-specific load) is required.

Environmental Grade:Choosing UV-stabilized or fire-rated versions based on the specific facility risks.

Technical Matrix

Resources

Technical Documents

Related Products

Explore More Specialized Technical Modules

Pumps

Screw Pump

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

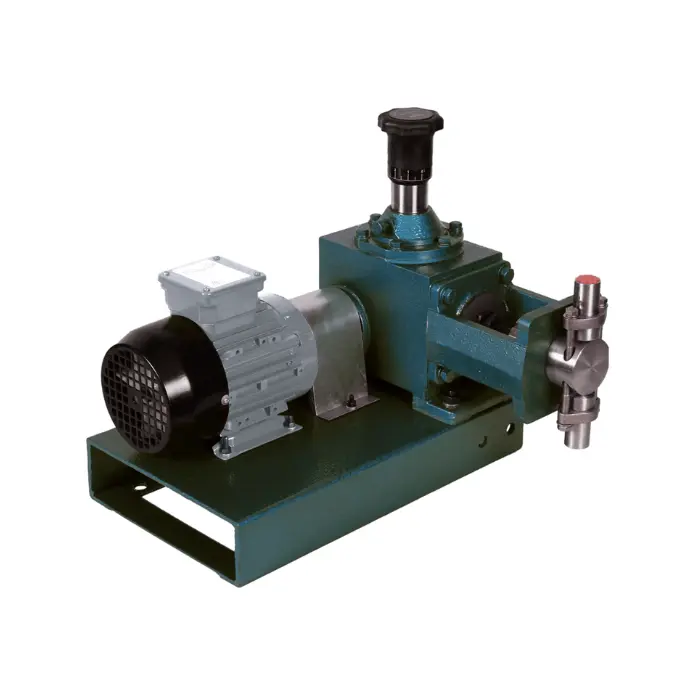

Plunger Metering Pump

Pumps

Screw Pump

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

Plunger Metering Pump

Performance

In Numbers

We deliver industrial excellence backed by two decades of precision manufacturing and global trust.