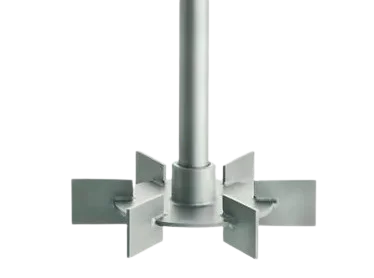

Mixing Impeller

High-performance industrial blades available in SS316, Hastelloy, and Titanium, engineered to optimize axial, radial, and high-shear flow patterns.

mixing

mixingSystem Advantages

1. Diverse Industrial Applications

Chemical Processing:Dissolving solids, creating stable suspensions, and ensuring reaction uniformity.

Pharmaceuticals:Precision blending of active ingredients and creation of stable emulsions.

Food & Beverage:Achieving homogenization, texture control, and consistent flavor blending.

Water Treatment:Specialized designs for flocculation, chemical dosing, and sludge processing.

Paints & Coatings:Critical for pigment dispersion and maintaining strict color consistency.

2. Key Impeller Types & Geometries

Propellers:Generate axial flow for low-viscosity blending and heat transfer applications.

Paddle Impellers:Flat-blade designs for gentle mixing and maintaining uniformity in large tanks.

Turbine Impellers:Versatile blades (including Rushton turbines) for gas dispersion and radial flow.

Hydrofoils:Thin, angled blades for high-efficiency axial flow in low-shear applications.

Anchor & Helical:Designed for high-viscosity materials and heat-sensitive wall-scraping duties.

High-Shear (Rotor-Stator):Intense shear for dispersing solids and creating fine emulsions.

3. Flow Pattern Characteristics

Axial Flow:Top-to-bottom circulation ideal for blending and solid suspension.

Radial Flow:Perpendicular flow creating high turbulence for gas-liquid mixing.

Tangential Flow:Circular motion along the tank circumference, suitable for vortex mixing.

Mixed Flow:A versatile combination of axial and radial patterns for multi-purpose mixing.

4. Engineering Selection Factors

Fluid Viscosity:Matching propeller types to low-viscosity or helical ribbons to high-viscosity fluids.

Shear Sensitivity:Selecting hydrofoils for delicate materials vs. rotor-stators for high-shear needs.

Tank Geometry:Optimizing blade selection based on tank height, width, and baffle arrangement.

Power Input:Aligning impeller torque requirements with available motor capacity to prevent energy waste.

5. Metallurgy & Surface Durability

Premium Stainless Steel:Standard SS316 and SS304 for pharmaceutical and food-grade hygiene.

Exotic Alloys:Hastelloy, Titanium, and Monel for aggressive chemical environments.

Advanced Coatings:Ceramic or polymer coatings for extreme heat or metal-free requirements.

Surface Processing:Options for high-mirror polishing, pickling, and passivation for corrosion resistance.

Technical Matrix

Resources

Technical Documents

Related Products

Explore More Specialized Technical Modules

Pumps

Screw Pump

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

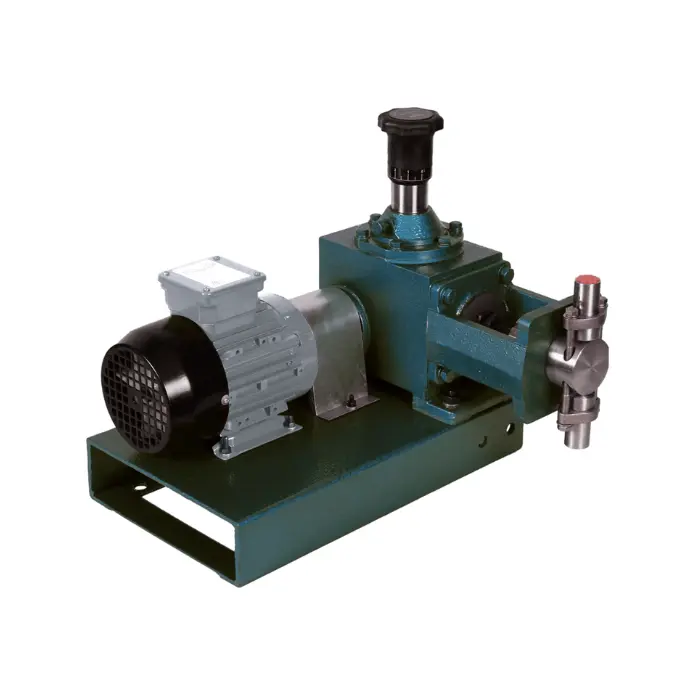

Plunger Metering Pump

Pumps

Screw Pump

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

Plunger Metering Pump

Performance

In Numbers

We deliver industrial excellence backed by two decades of precision manufacturing and global trust.