Screw Pump

A rotary positive displacement pump designed for smooth, continuous flow of viscous and abrasive fluids.

screw

screwSystem Advantages

1. Mixing Expertise

Process Flow & Optimization

Reaction Rates:Creating optimal flow patterns to accelerate conversion.

Mass Transfer:Ensuring reactants are uniformly distributed.

Rotor & Stator Geometry

The pump consists of a precisely machined metallic rotor and an elastomer stator. The unique geometry maintains an effective sealing line under both static and dynamic conditions, ideal for

Pulsation-Free Flow

The cavities progress smoothly from the suction side to the discharge end, carrying the fluid without pulsation, which is critical for protecting downstream equipment.

Technical Matrix

Technical

FAQ

Expert insights on installation, maintenance, and performance optimization for your Screw Pump.

Related Products

Explore More Specialized Technical Modules

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

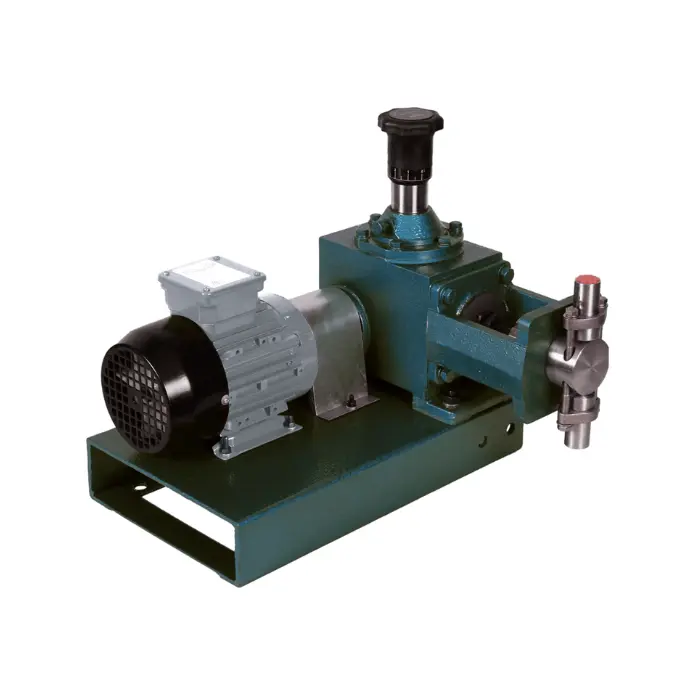

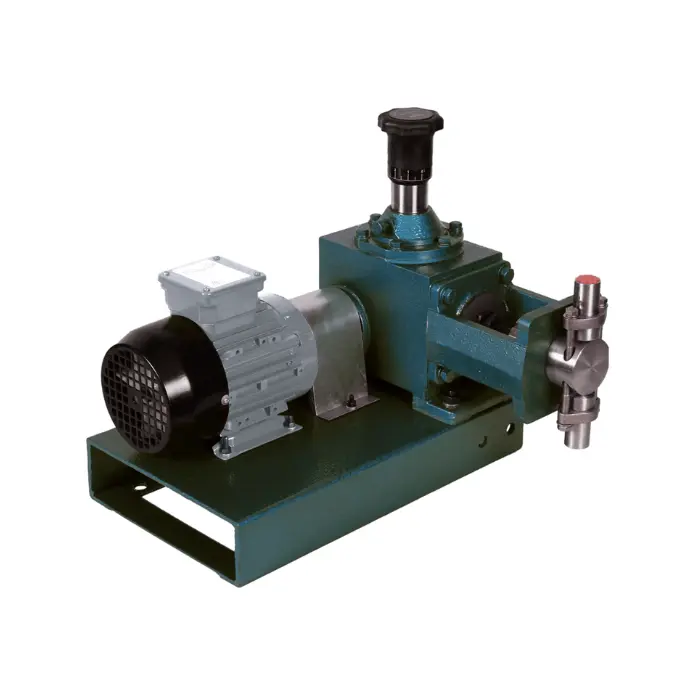

Plunger Metering Pump

Pumps

Triplex Plunger Pumps

Pumps

Electronic Dosing Pump

Pumps

Electronic Metering Pumps

Pumps

Hydraulic Diaphragm Pump

Pumps

Mechanical Diaphragm Pump

Pumps

Plunger Metering Pump

Pumps

Triplex Plunger Pumps

Performance

In Numbers

We deliver industrial excellence backed by two decades of precision manufacturing and global trust.