Heavy Duty Agitators are designed for large volume Vessels which are reliable for most demanding heavy industrial applications, from pharmaceutical fermentation, hydrogenation, bio digesters, chemical reactors, resins, large-scale chemical processing to minerals processing and heavy sludge waste treatment.

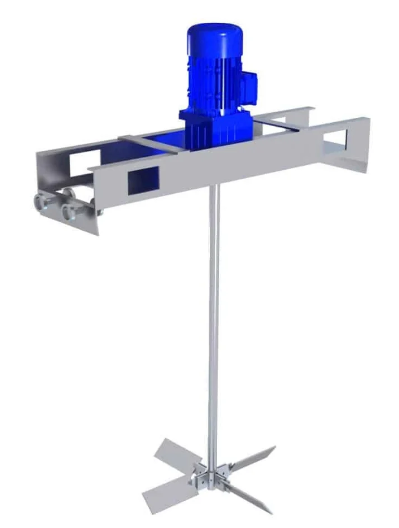

Radial and axial loads on the drive are completely absorbed by a separate double bearing section and the flexible coupling connecting the mixer shaft to the drive. These Heavy Duty Industrial mixer has a rigid torsion-free Bearing housing.

Applications of Heavy-Duty Agitators

- Chemical Processing: Ideal for blending, suspending, and emulsifying chemicals, especially in large reactors. They are used in processes like polymerization, oxidation, and neutralization, where materials may be highly viscous or corrosive.

- Pharmaceutical Production: Heavy-duty agitators are essential in producing active pharmaceutical ingredients (APIs) and bulk drugs, as they ensure thorough mixing and even distribution of compounds, critical for quality control.

- Food and Beverage: Used for mixing thick substances like sauces, syrups, and pastes or in high-volume applications, such as blending large vats of liquid ingredients.

- Mining and Mineral Processing: Heavy-duty agitators mix slurries, suspending solids and promoting reactions in processes like leaching and extraction, which require robust and reliable equipment.

- Wastewater Treatment: In applications involving sludge or slurry mixing, heavy-duty agitators ensure even distribution of substances, essential for aerobic and anaerobic processes.

Design and Types of Heavy-Duty Agitators

- Top-Entry Agitators: These are mounted on the top of the tank and are suited for large tanks and high-viscosity substances. Common in chemical processing and wastewater treatment.

- Side-Entry Agitators: Mounted on the side of the tank, these are suitable for large storage tanks where vertical space is limited, often used for blending liquids and keeping particles suspended.

- Bottom-Entry Agitators: Used in cases where top or side access isn’t ideal, bottom-entry agitators are frequently found in pharmaceutical applications that require high levels of cleanliness.

- Portable Heavy-Duty Agitators: Designed for flexibility, these portable units can be attached to various tanks and vessels, commonly used in batch mixing or intermittent operations.

Key Features of Heavy-Duty Agitators

- Powerful Motors: Heavy-duty agitators are equipped with high-torque motors that can handle demanding mixing conditions, including high-viscosity substances and large batch sizes.

- Rugged Construction: Constructed with durable materials like stainless steel, Hastelloy, or even titanium for aggressive environments, ensuring resistance to corrosion, wear, and mechanical stress.

- Robust Bearings and Shafts: Reinforced bearings and thick shafts help handle heavy loads and prevent bending or breaking during operation.

- Advanced Sealing Systems: Heavy-duty agitators often use mechanical seals to contain volatile substances, prevent leaks, and protect sensitive components from harsh chemicals or high pressures.

- Variable Speed Control: Many heavy-duty agitators feature variable frequency drives (VFDs) to allow speed adjustment, critical for processes requiring different mixing intensities.

4. Impeller Designs for Heavy-Duty Agitators

- Anchor Impellers: Designed to scrape tank walls, anchor impellers are ideal for mixing high-viscosity fluids and preventing buildup, commonly used in food and cosmetics.

- Paddle Impellers: Provide effective mixing with low shear, making them suitable for gentle blending of fragile ingredients or for suspending solids.

- Helical or Spiral Impellers: These impellers offer high axial flow, moving materials from the bottom of the tank upwards, which is useful for thick slurries and high-viscosity liquids.

- Turbine Impellers: Known for generating radial flow, turbine impellers are used in chemical reactions where rapid mixing and shearing are needed.

Advantages of Heavy-Duty Agitators

- Efficient Mixing for High-Viscosity Materials: Their powerful motors and specialized impellers allow them to handle thick, dense, and sticky substances that standard agitators struggle with.

- Consistency and Homogeneity: Heavy-duty agitators ensure consistent mixing across large volumes, critical in industries where product quality and uniformity are essential.

- Longevity in Challenging Conditions: Their rugged design ensures durability, reducing downtime and maintenance in harsh environments.

- Energy Efficiency: Though powerful, many heavy-duty agitators are designed to optimize power use, making them more energy-efficient than other high-power equipment.

Design Considerations

- Material Compatibility: The choice of materials, such as stainless steel or exotic alloys like Hastelloy, depends on the chemicals or materials being mixed. Material compatibility ensures resistance to corrosion, erosion, and chemical degradation.

- Operating Conditions: Heavy-duty agitators must be rated to handle extreme pressures and temperatures in processes like chemical synthesis or petrochemical refining.

- Seal Type: Mechanical seals must be compatible with the process conditions to prevent leaks and contamination, particularly important in hazardous or sterile environments.

- Maintenance and Accessibility: Heavy-duty agitators should be designed for easy access to parts like seals, bearings, and impellers, as regular maintenance is necessary for optimal performance in demanding applications.