Over the past few years, the demands for Mixing systems in industrial uses have consistently risen. Thus, Datgur offers diverse range of mixing impellers designed with distinct performance attributes to fulfill a variety of application needs. The design of the Impeller blades, the choice of an appropriate mixing setup, and the arrangement of the agitator parts have a significantly impact both the process-related and mechanical characteristics. Each of our impellers are manufactured with 316 Stainless Steel material as the standard option. However, we also have alternatives such as 304 Stainless Steel, Mild Steel/Carbon Steel, Hastelloy, Titanium, and other premium alloy versions for most impeller designs as per the application. We also offer various surface treatments like polishing, coatings, and pickling and passivation processing.

Applications of Mixing Impellers

Mixing impellers are used across industries for various purposes:

- Chemical Processing: For dissolving chemicals, creating suspensions, and achieving reaction uniformity.

- Pharmaceuticals: Used to blend active ingredients, create emulsions, and ensure consistent drug formulations.

- Food and Beverage: Employed for tasks such as homogenization, flavor blending, and texture control.

- Water and Wastewater Treatment: Used for flocculation, chemical dosing, and sludge processing.

- Paints and Coatings: Critical for pigment dispersion, solvent blending, and maintaining color consistency.

Key Types of Mixing Impellers

Different impeller designs are suited to various mixing needs and materials:

- Propellers: Similar to marine propellers, these impellers generate axial flow (parallel to the shaft). They are effective for low-viscosity liquids, providing efficient flow without excessive shear. Common in blending, circulation, and heat transfer applications.

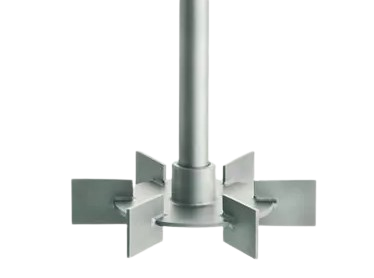

- Paddle Impellers: Consisting of flat blades mounted on the impeller shaft, paddle impellers create gentle mixing with low shear, suitable for blending and maintaining uniformity in larger tanks.

- Turbine Impellers: These impellers have multiple blades and can generate either axial or radial flow. They are versatile, used in a wide range of applications, from low to moderate viscosity, for blending, gas dispersion, and heat transfer.

- Rushton Turbine: Known for its radial flow pattern, the Rushton turbine is widely used in gas-liquid mixing.

- Hydrofoil Impellers: Featuring thin, angled blades, these impellers create high-efficiency axial flow and are ideal for low-shear applications, such as blending large volumes of liquid.

- Anchor and Helical Impellers: Designed for high-viscosity materials, these impellers are often used in highly viscous mixing or heat-sensitive applications. Anchor impellers sweep along the tank wall, while helical ribbon impellers move material both radially and axially.

- High-Shear Impellers: These include designs like rotor-stator impellers, which create intense shear suitable for dispersing solids and creating emulsions, commonly used in food, cosmetics, and pharmaceuticals.

Flow Patterns Created by Impellers

- Axial Flow: Impellers like propellers and hydrofoils push liquid in the direction of the shaft, creating top-to-bottom circulation. Ideal for blending and solids suspension, axial flow helps create a uniform mixture by circulating the contents vertically.

- Radial Flow: Impellers such as flat-blade turbines produce flow perpendicular to the shaft. Radial flow generates high shear and turbulence, making it effective for gas-liquid mixing and dispersing solids in liquids.

- Tangential Flow: Some impellers produce tangential flow, which moves along the circumference of the tank and is suitable for creating vortex mixing.

- Mixed Flow: Many impellers produce a combination of axial and radial flow. This flow type is versatile, balancing shear and circulation for various mixing applications.

Factors in Choosing the Right Impeller

- Viscosity of the Fluid: The viscosity of the material affects the type of impeller needed. Low-viscosity liquids mix well with propellers, while high-viscosity materials often require anchors, paddles, or helical impellers.

- Shear Requirements: High-shear mixing, needed for creating emulsions or dispersions, calls for impellers like high-shear mixers or rotor-stators. For delicate materials, low-shear impellers like hydrofoils are preferred.

- Mixing Purpose: If the goal is blending or homogenization, axial flow impellers are usually ideal. If dispersion or breaking down particles is required, radial or high-shear impellers are preferred.

- Tank Design: The size, shape, and baffle arrangement of the tank influence impeller selection. For example, axial flow impellers work well in tall, narrow tanks, while radial flow impellers are often used in wider tanks.

- Power Input: Each impeller type has different power requirements. Selecting an impeller that matches the available motor capacity is essential to avoid energy waste and achieve efficient mixing.

Impeller Materials and Durability

Impellers are typically made from materials that resist wear and corrosion:

- Stainless Steel: Widely used in the food, pharmaceutical, and chemical industries due to its resistance to corrosion, ease of cleaning, and durability.

- Plastic or Polymer Coatings: Suitable for lightweight, non-corrosive applications, or where metal contamination must be avoided.

- Hastelloy and Other Alloys: Used in highly corrosive environments, like chemical processing, where stainless steel may not withstand the aggressive substances.

- Ceramic-Coated Impellers: Resistant to extreme heat and chemical corrosion, suitable for specific applications in high-temperature or aggressive chemical environments.

Advantages of Using the Right Impeller

- Improved Mixing Efficiency: By matching the impeller to the process requirements, operators achieve faster, more consistent results.

- Lower Energy Consumption: Optimized impeller selection ensures effective mixing without wasting energy, reducing operating costs.

- Product Quality and Consistency: Impellers designed for specific tasks (e.g., emulsification, blending) result in uniform product consistency and quality.

- Reduced Maintenance Costs: Using impellers made from durable materials extends their lifespan and minimizes downtime due to wear and tear.